The thoughts, details and conclusions contained within this blog really should not be construed as conclusive reality, ValGenesis supplying guidance, nor as an indication of long term results.

Revalidation is a lot more commonly employed for professional medical equipment than drug merchandise. It's executed when possible validation reaches a summary which the manufacturing process is not able to supply the merchandise consistently.

On the list of essential elements highlighted in the FDA guidelines is the necessity for a robust validation learn program. This strategy serves for a roadmap to the validation actions and makes certain that all required actions are taken to validate the process.

This is often achieved by gathering and analyzing info from multiple manufacturing operates to make certain that the process is stable and capable of Conference the demanded quality attributes.

On top of that, you would like in order that your workforce has established all needed specs and calibrations to maintain consistency.

"While in the realm of process validation, undocumented effects are pretty much as good as none." In my perspective: one. Use standardized templates for regularity in reporting.

The 2nd phase entails demonstrating the process is capable of persistently manufacturing items that fulfill the predetermined top quality attributes. It consists of the execution of validation protocols to verify the process overall performance and the gathering of information to assist the validation.

ValGenesis Process Perception brings together unit functions processes with the integration around the lifecycle. Conduct click here process mapping, electronic continued process verification, and process lifecycle management of your total product portfolio — all in one System.

The FDA's Process Validation Direction provides a comprehensive framework to the validation of pharmaceutical processes. It outlines a danger-primarily based solution that takes into consideration the prospective influence on product or service good quality and affected person basic safety.

Every single of these levels plays an important position in ensuring the manufacturing process is effective at regularly developing substantial-quality solutions.

In its Process Validation: Normal Rules and Tactics Steering, the FDA defines process validation as "the gathering of knowledge within the click here process design stage all through manufacturing, which establishes scientific evidence that a process is capable of constantly providing top quality merchandise."

To overcome validation challenges, it is vital to take a position in coaching and education on regulatory necessities.

In addition, process layout requires the choice of ideal equipment and services which will be Employed in the manufacturing process. Factors for example potential, dependability, and compatibility Using the process specifications are taken under consideration to be sure smooth and economical functions.

Products and services need approval to display precision and top quality. Acceptance procedures are employed to ensure shoppers and consumers from anything they profit.

Jennifer Grey Then & Now!

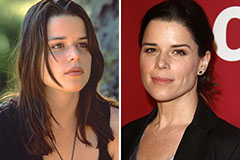

Jennifer Grey Then & Now! Neve Campbell Then & Now!

Neve Campbell Then & Now! Brandy Then & Now!

Brandy Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!